RTTLIT S10 | P20 | E20

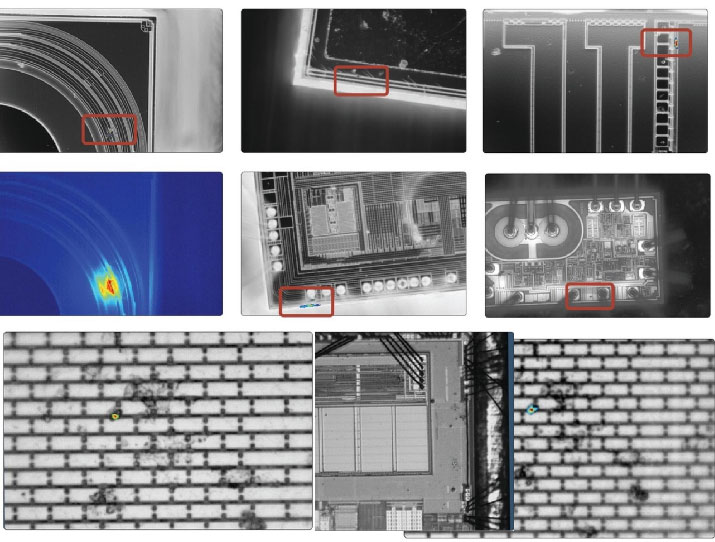

Real-Time Transient Lock-In Thermography System

The RTTLIT Series delivers advanced lock-in thermography for precise, reliable, and efficient failure analysis across electronic manufacturing and research environments.

Extended Performance – P20 & E20

For more demanding semiconductor and wafer-level applications, the P20 and E20 models feature enhanced cooled detectors and higher-resolution imaging to support advanced R&D and production needs.

Hikcode (海克德)

Industrial Barcode Readers & Scanners

Hikcode provides cutting-edge barcode reading solutions engineered for precision, speed, and reliability in industrial and EMS environments.

AUBO Robotics (遨博智能)

AUBO collaborative robots (cobots) are engineered for precision, safety, and flexibility in electronics manufacturing and assembly (EMS). With payload capacities ranging from 3 kg to 35 kg, the AUBO iH and iS series empower manufacturers to achieve higher efficiency, quality, and reliability across production lines.

Autonomous Mobile Robots (AMR) – Xunji (寻迹)

Smart Logistics Solutions for Modern Electronics Manufacturing

Xunji AMRs deliver flexible, intelligent, and automated material handling designed to streamline operations in electronics manufacturing and assembly environments. Built with advanced navigation and seamless system integration, our AMRs enhance efficiency, safety, and scalability across production lines and warehouses.