In addition to standard solutions, we provide non-standard, custom-designed equipment to meet the specific inspection, testing, and automation needs of EMS providers. Our modular systems ensure flexibility, precision, and efficiency across diverse manufacturing processes.

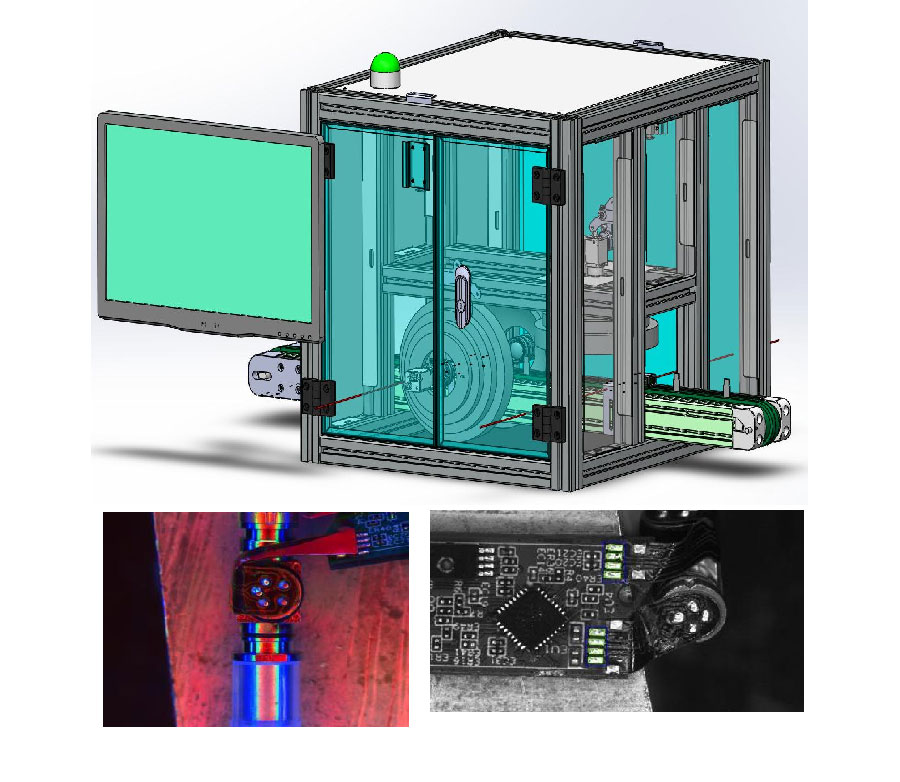

Optical Module SFP Vision Inspection Machine

Designed for high-precision inspection of optical modules, ensuring product quality through advanced vision technology.

Inspection Capabilities:

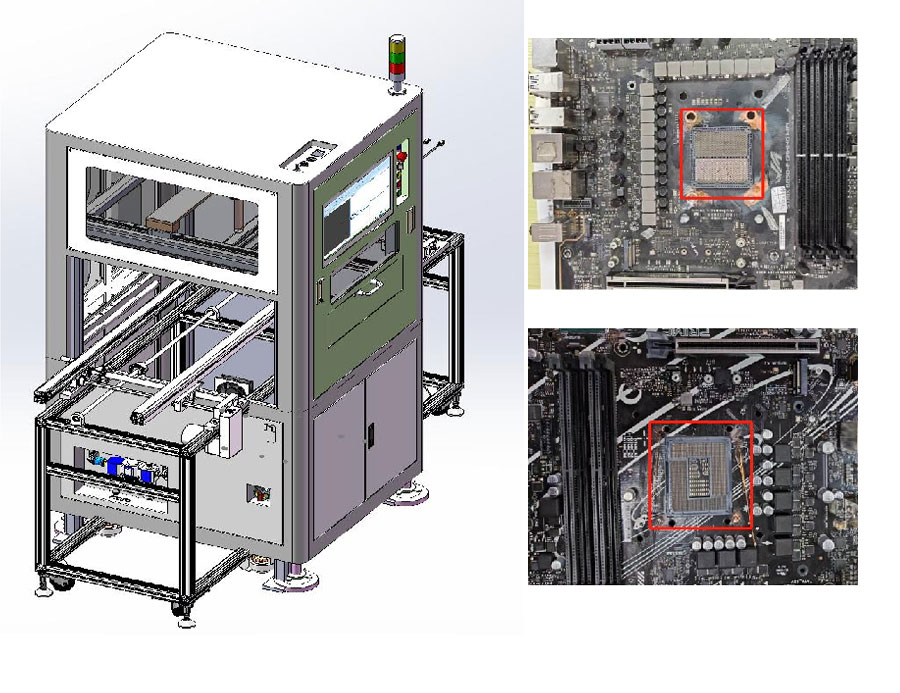

CPU Inspection Machine

High-speed automated inspection system tailored for CPU production lines.

Inspection Capabilities:

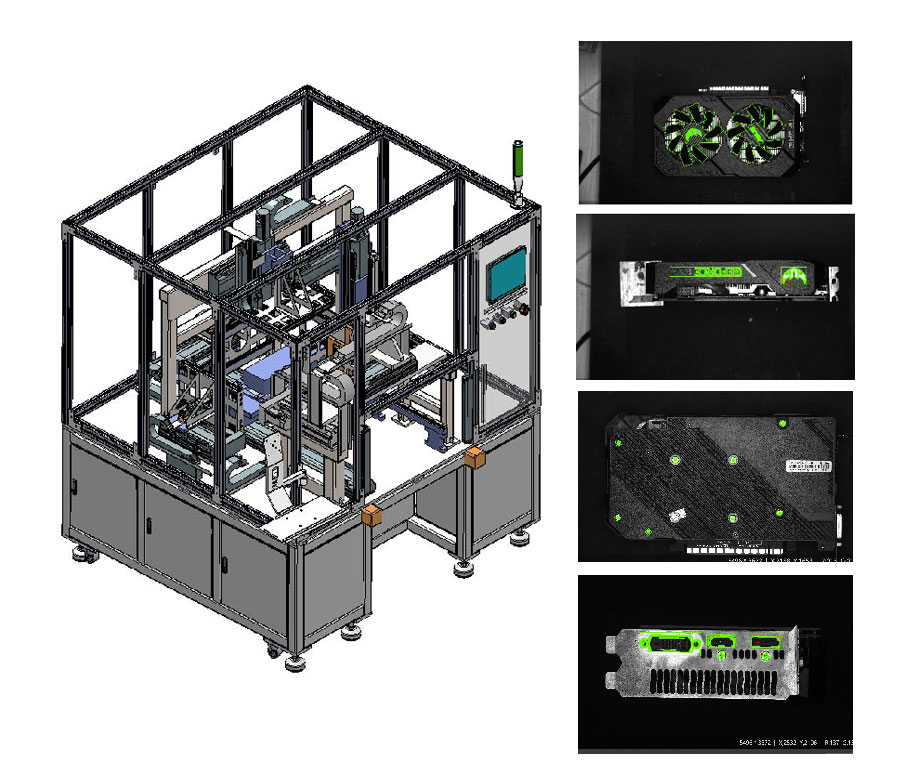

Six-Side Inspection Machine

Comprehensive 360° inspection to ensure product integrity and traceability.

Inspection Capabilities:

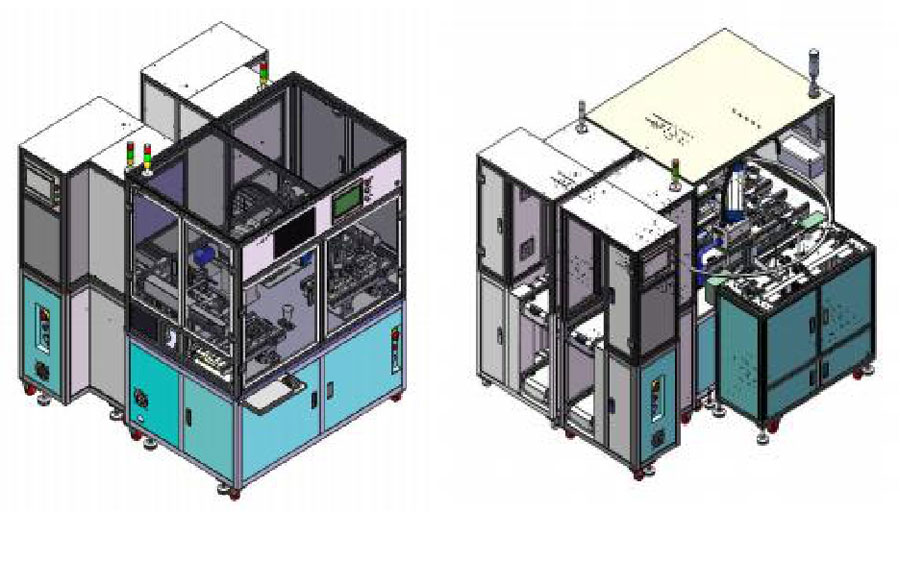

Flex Automation Systems

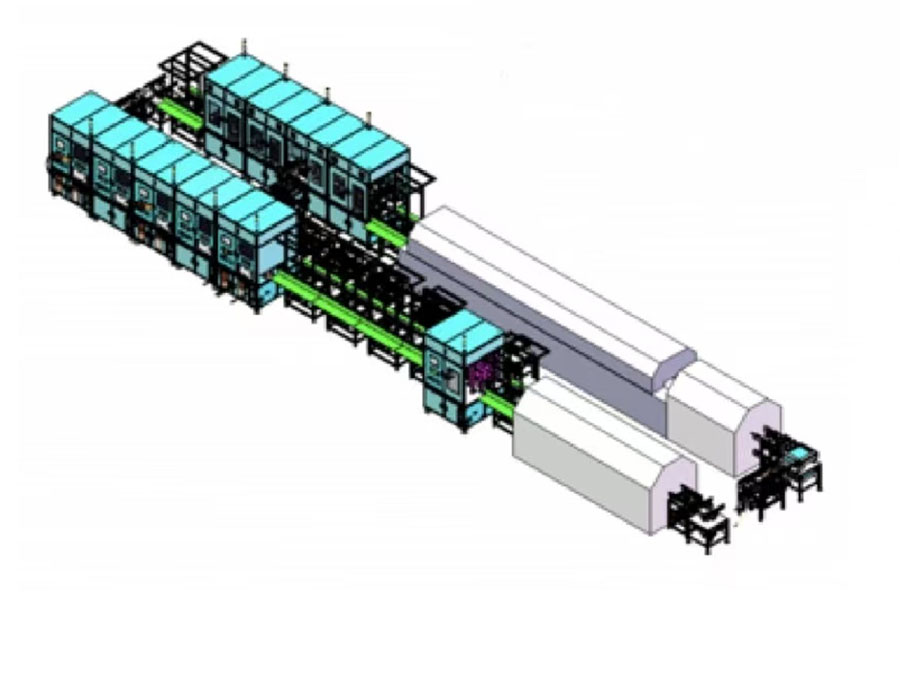

Heat Sink Automatic Assembly Line

A fully modular assembly solution for heat sink production.

Key Functions:

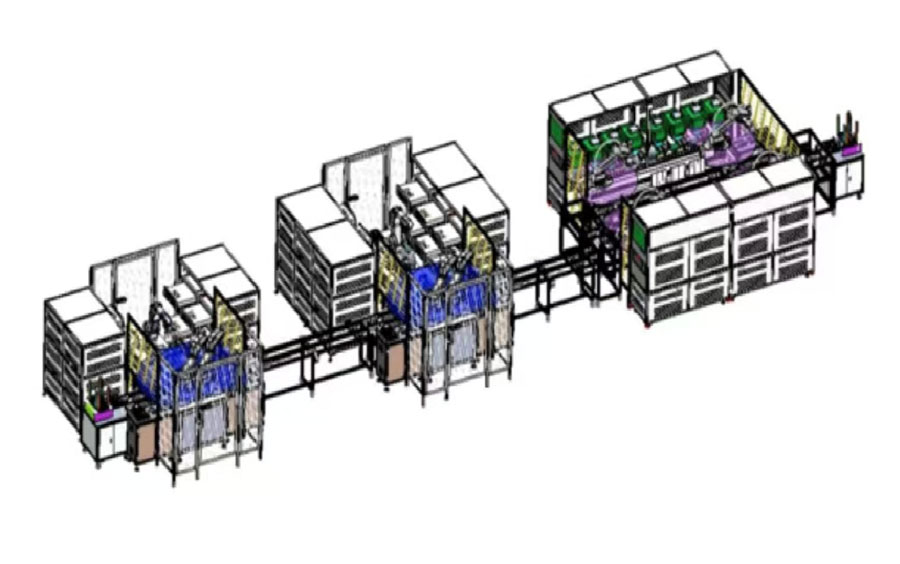

DFU-FCT-Mica Automated Test Handler

An advanced system integrating automated test and handling functions for electronic modules.

Key Features: